在线咨询

在线咨询

¥ 2043.00

¥ 2043.00

¥ 2043.00

¥ 2089.00

¥ 2089.00

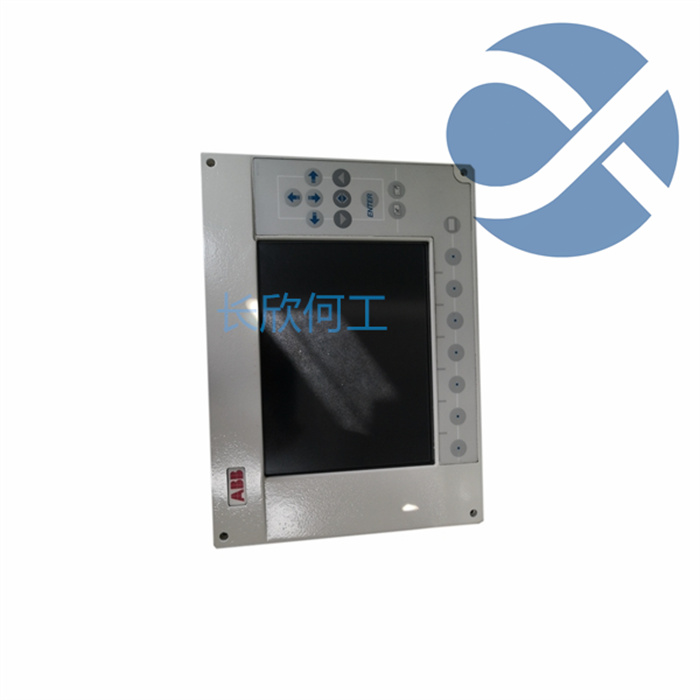

易卖工控网(www.ymgk.com)提供”GCC960C102 Inverter control cabinet logic board”,产品详情:品牌/厂家:ABB +8615359293870、型号:GCC960C102+8615359293870、成色:全新、货期:现货 1天内发货、保修:180天,更多产品详情就上易卖工控网。

From a developmental perspective:

DCS has evolved from traditional instrument panel monitoring systems. Therefore, DCS is inherently more focused on instrument control, For example, the YOKOGAWA CS3000 DCS system we use does not even have a limit on the number of PID (PID, proportional differential integration algorithm, is the standard algorithm for closed-loop control of regulating valves and frequency converters, and the number of PID usually determines the number of regulating valves that can be used. PLC has evolved from traditional relay circuits, and the initial PLC did not even have the ability to handle analog signals. Therefore, PLC emphasized logical operation ability from the beginning.

From the perspective of system scalability and compatibility:

There are many control products in the market, both DCS and PLC, which are produced and sold by many manufacturers. For PLC systems, there is generally no or very little demand for expansion, as PLC systems are generally designed for equipment use. Generally speaking, PLCs also rarely have compatibility requirements, such as the requirement for resource sharing between two or more systems, which is also very difficult for PLCs. Moreover, PLCs generally adopt dedicated network structures, such as Siemens' MPI total linear network, and even adding an operator station is not easy or costly. During the development process of DCS, various manufacturers have their own systems. However, most DCS systems, such as Yokogawa YOKOGAWA, Honeywell, ABB, and so on, although the communication protocols within the system (process level) are not the same, the network platforms at the operation level all choose Ethernet networks and use standard or modified TCP/IP protocols. This provides convenient scalability. In this type of network, both the controller and the computer exist as a node, and as long as the network reaches its destination, the number of nodes can be increased or decreased and the position of nodes can be arranged arbitrarily. In addition, based on open protocols such as OPC and DDE in Windows systems, various systems can also communicate conveniently to achieve resource sharing.

Contact information: 15359213550

Contact person: He Gong

Email: geabbdcs@gmail.com 386353502@qq.com

Official website: https://www.gyamazon.com , http://www.geabb.com

What are the issues to pay attention to when modifying the wiring connector?

Connection connector issue

The connection head was not soldered or poorly soldered, resulting in virtual soldering;

The thermal cycle causes the joint to loosen;

Loose bolt connection points caused by vibration;

The connection point has poor contact due to corrosion.

6. What aspects can be analyzed for power failure correction?

Power supply issue

Power supply issues are divided into power connection issues and power quality issues.

Power connection issue

Including: no connection (one of the fire, ground, and zero items is not connected); Wrong wiring (reverse connection between live wire and neutral wire, reverse connection between ground wire and neutral wire, multiple short circuits between ground wire and neutral wire).

Power quality issues

Including: quality of equipment wiring (loose connectors); The technical indicators (voltage, frequency, etc.) exceed the specified requirements.

Line quality issues

Including: increased impedance of power lines and poor insulation layer.

Polar issues

Including: an increase in ground electrode resistance and disconnection of the ground electrode from the ground grid.

environmental problems

Including: unreasonable wiring of power lines, especially ground wires, and being too close to wires and equipment that generate strong magnetic field interference.

7. How to deal with abnormal data display in a certain input channel?

Solution: Disconnect the on-site signal of this channel from the I/O module terminal, use an analog signal source to send a signal that is the same as this on-site signal to this channel, and observe whether the displayed value on the CRT returns to normal. If it is normal, it indicates that the problem is on the signal side of the site. You can search and solve it according to the method mentioned earlier; If it is still abnormal, it indicates that the problem is within the MACS system